NorDan UK, one of Europe’s leading high-performance windows and doors manufacturers, has launched Dynamic Environmental Product Declarations (EPDs), a new tool that will transform the way whole life carbon is measured within design projects, giving architects and specifiers greater control on sustainable product choices.

Unique to the NorDan Group worldwide, Dynamic EPDs go beyond the basic calculations of standard ‘static’ EPDs, generating precise carbon data for individual products and entire developments. This provides architects and specifiers with a new level of carbon transparency, offering more flexibility and adaptability when designing and specifying a new build or refurbishment development.

Craig Greenwood, CEO of NorDan UK, said, “The industry is increasingly demanding precise carbon cost insights for design projects as we strive to meet the UK’s Net Zero targets, so architects are under pressure to provide this information quickly and accurately.

“Through ‘Dynamic EPDs’ we’re providing them with a solution. Architects and specifiers can get a more accurate understanding of the associated carbon than ever before. We then collaborate with them to ensure they have the right NorDan UK product to meet their design specification.”

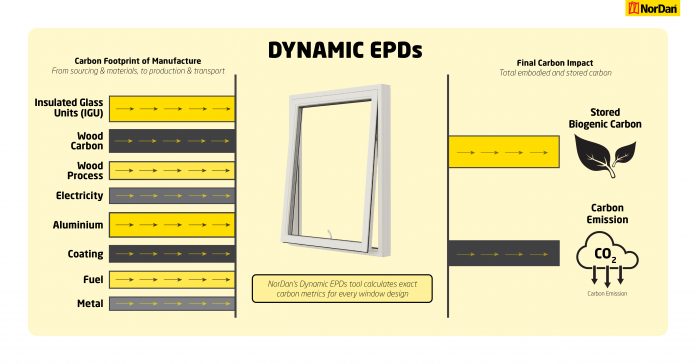

The tech, which uses a custom-built back-end system, can understand each carbon variable within a design specification, including embodied carbon, operational carbon (Scope One and Two) and Indirect Greenhouse Gas (GHG) emissions (Scope Three).

Dynamic EPDs are generated based on the correct size of each window being used and are also responsive to changes in materials, including specific glazing, production methods and regulatory requirements, ensuring continuous compliance and relevance.

The introduction of Dynamic EPDs reflects the industry drive towards hyper-specific project data, such as assigning unique identification numbers to building components. Dynamic EPDs complement this trend, offering a corresponding unique EPD for every identified product.

Although it was one of the first manufacturers in Europe to invest in ‘static’ EPDs on its entire product range, NorDan UK says it recognised the limitations of ‘static’ EPDs because they do not always provide a clear picture at a project level, particularly as windows are often custom-made. Dynamic EPDs provide the in-depth, granular data that architects need to make informed, sustainable choices.