Deep Water Blue, a leading provider of water treatment solutions, has announced the availability and proven benefits of ODACON film-forming chemistry for Waste-to-Energy (WtE) facilities, gas-fired power stations, and biomass plants across the UK and Ireland. This technology, licensed by Reicon, offers exceptional corrosion protection and operational efficiency improvements for high-pressure steam systems operating under the demanding conditions typical of modern power generation facilities.

Where power stations have moved away from using legacy oxygen scavengers like hydrazine, the shift has left steam systems more exposed to oxygen-related corrosion. This is especially prevalent as modern plants frequently shut down, restart, and adjust output to manage grid demand. These flexible operations are now common, but create new vulnerabilities in turbine, condenser, and steam cycle components.

Where power stations have moved away from using legacy oxygen scavengers like hydrazine, the shift has left steam systems more exposed to oxygen-related corrosion. This is especially prevalent as modern plants frequently shut down, restart, and adjust output to manage grid demand. These flexible operations are now common, but create new vulnerabilities in turbine, condenser, and steam cycle components.

As Deep Water Blue’s water treatment consultant George Nixon explains, “ODACON replaces outdated, hazardous chemicals with an advanced film-forming treatment that, in one simple step, covers the entire water-steam system from the boiler right through to turbines and condensers, helping power stations protect their assets even while demand is fluctuating.”.

By adding a molecular coating to system surfaces, ODACON shields against both oxygen corrosion and flow-assisted corrosion, key threats during frequent load changes and stop-start cycles. As George highlights, “This means power stations can count on enhanced corrosion protection to maintain reliable operation and extend the life of their equipment.”

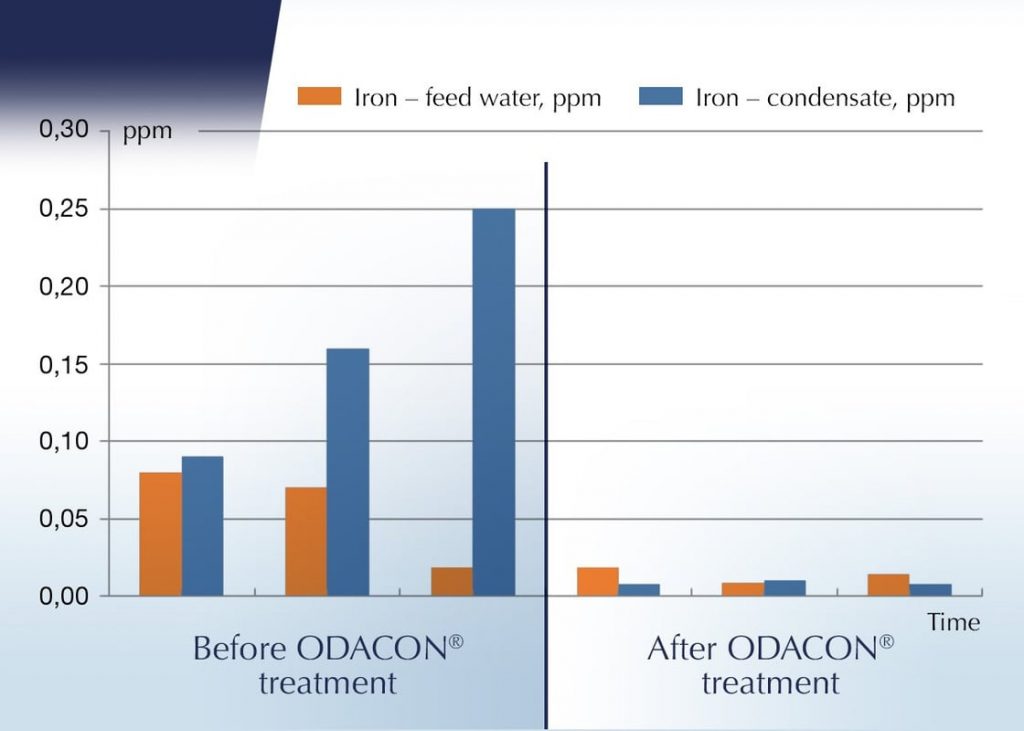

Recent projects underlining the proven value of ODACON include the 800MW combined cycle gas turbine (CCGT) power plant in at Statkraft Germany, where it delivered a 50% reduction in re-commissioning time and a 70% reduction in iron concentration in intermediate pressure sections during restart. The treatment also eliminated the need for nitrogen blanketing and complex drying procedures, significantly simplifying operational requirements while providing robust corrosion protection.

In a Swedish biomass facility operating at 144 t/h steam capacity, ODACON led to the complete elimination of Flow Accelerated Corrosion (FAC) in critical components. It also transformed red haematite oxides into a protective grey magnetite layer, reduced turbine deposits and scale formation from boiler carry-over, and enhanced drying capabilities during shutdown periods.

Efficiency gains are another major advantage, with ODACON gently cleaning legacy deposits and encouraging the transformation of red haematite into a protective magnetite layer on heat transfer surfaces.

ODACON has a very low dosage requirement, is easy to integrate into existing power plant control systems. Its proven record across fossil, combined cycle, and biomass plants is supported by guidance from leading industry groups, including IAPWS TGD 8-16 (2019).