Intelligent Energy (IE), a leading UK fuel cell developer and manufacturer, unveils its IE-FLIGHT family of aviation fuel cell products for sub-regional and regional aircraft, marking a development milestone towards realising sustainable aviation.

IE-FLIGHT fuel cell system products offer the following benefits:

- Market-leading power densities

- High-temperature heat rejection architecture allows the fuel cell system to operate at high temperatures – enabling a smaller heat exchanger for less weight and aircraft drag

- Class-leading transient response times

- True zero-emissions flight

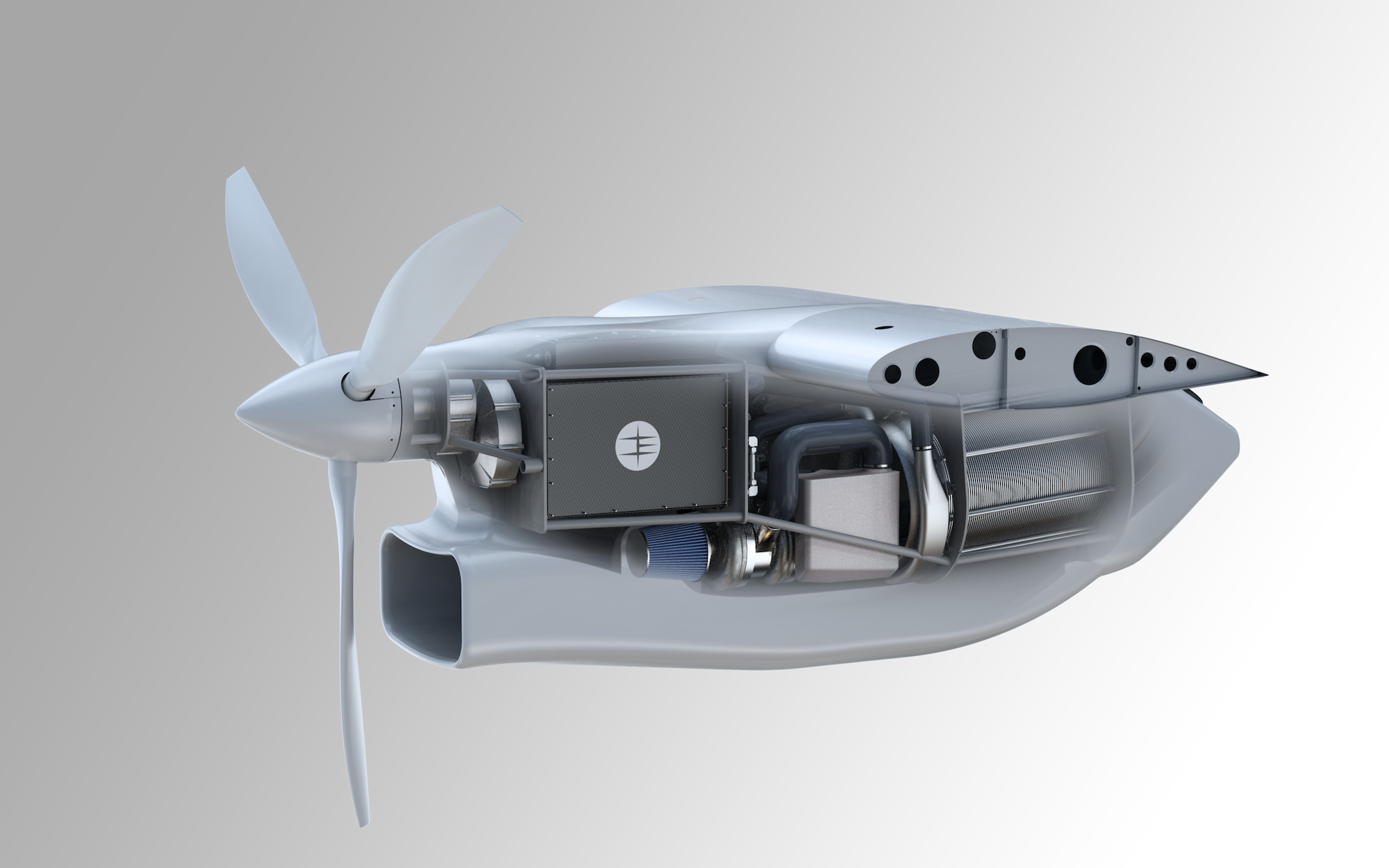

The British company’s IE-FLIGHT F300 Fuel Cell System will be unveiled at the upcoming Farnborough International Airshow (22-26 July) and is suitable for use across eVTOL, sub-regional and regional aircraft applications. The IE-FLIGHT F300 can be either installed on new Part-23 aircraft designs, or retrofitted onto existing Part-23 aircraft. The IE-FLIGHT architecture is scalable for multi-MW fuel cell installations, making it suitable for Part-25 aircraft as well.

The aviation industry’s shift towards zero-emission solutions is being driven by the need to reduce greenhouse gas emissions. It currently contributes 2-3% of global emissions and this is projected to rise to 8-15% by 2050, based on air transport passenger traffic growth forecasts.

Intelligent Energy’s IE-FLIGHT products represent a significant advancement in the aviation industry’s journey towards zero-emission flights and have a number of operational and environmental benefits, including:

Smaller heat exchanger

The IE-FLIGHT fuel cell uses a patented evaporative cooling technology which redefines efficient thermal performance. This technology enables the operation of the fuel cell system at high temperatures, allowing a much smaller heat exchanger to be used – reducing weight, drag and enhancing overall aircraft performance, particularly at higher speeds.

Fewer moving parts and components

Intelligent Energy’s fuel cell system features significantly fewer mechanical moving parts compared to traditional aircraft gas turbine or piston engines, and with advanced fuel cell performance monitoring methods, the IE-FLIGHT fuel cell system’s health can be accurately monitored to give operators confidence in planning service intervals.

Compared to typical PEM fuel cell systems, the IE-FLIGHT system has a simplified Balance of Plant with fewer components. This increases power density, reliability and reduces cost at volume production.

True zero emissions

While sustainable aviation fuel (SAF) is competitive with traditional kerosene, it is still not truly zero-emission and is costly to produce. Hydrogen is an appealing alternative because it produces zero emissions within fuel cells, can be produced locally, and refuelling times are comparable to those associated with traditional aviation fuels.

Developed for aviation

Alternative fuel cell products have been created by adapting automotive fuel cell systems for use within aviation. Intelligent Energy has taken a fundamental approach of developing a core fuel cell stack specifically for use within aviation, making IE-FLIGHT fuel cell products fit for purpose within future aircraft certification programmes.

Jonathan Douglas-Smith, Head of Sales for Aerospace at Intelligent Energy, said, “Building on our 23 years of developing fuel cell systems, we have been able to develop a bespoke solution for the aerospace industry during the last four years which features a patented high-temperature operation architecture that doesn’t exist in any other fuel cell product. Although our IE-FLIGHT F300 launch product is suitable for Part-23 aircraft, our IE-FLIGHT technology can be scaled up to accommodate aircraft within the Part-25 sector as well.”

For detailed technical information relating to the high-temperature architecture, please click: www.intelligent-energy.com/wp-content/uploads/2024/07/FLIGHT-Whitepaper.pdf