Marginal Abatement Cost Curves (MACC) show where money can be best spent and allows comparisons between different environmental strategies in order to decide which will achieve the greatest impact for the least cost. Here Neil Frater, Optimization Manager from Atlas Copco asks what can MACC tell us about compressed air systems?

It can be difficult to know what’s the best investment to make in new technology for environmental benefits. There are obvious options such as installing LED lighting or behavioural changes such as turning off unwanted lights or not leaving taps running while washing hands. But how do you make data-based decisions between them? One method of ranking these options is by using a tool designed by McKinsey & Company, the multinational strategy and management consulting firm, namely Marginal Abatement Costs Curve or MACC for short. A MACC allows the user to compare the cost-effectiveness of carbon dioxide (CO2) reduction options in the context of CO2 emissions savings. Allowing the comparison of apples with apples across seemingly incomparable applications.

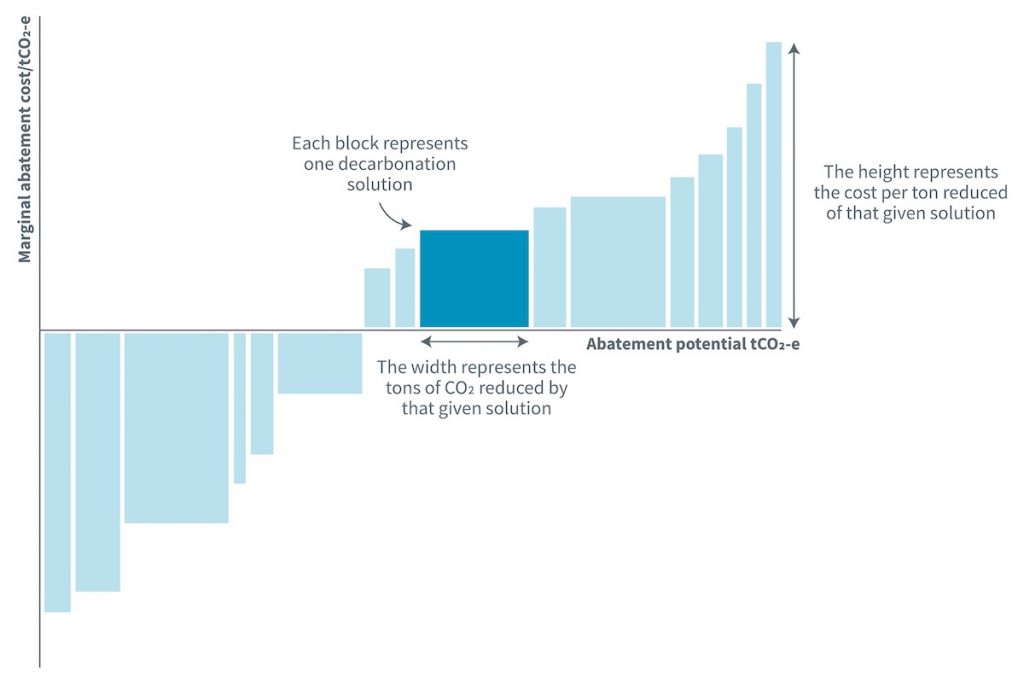

The vertical axis (y-axis) of the MACC shows the cost-effectiveness (£/tCO2) based on NPV (net present value) costs and lifetime CO2 savings while the horizontal axis (x- axis) shows the annual carbon savings. The cumulative annual savings (the full width of all the blocks on the MACC) give an indication of the maximum potential carbon savings. The MACC also includes a list of the measures in decreasing order of cost-effectiveness (£/tCO2).

The use of a MACC allows an informed selection of the efficacy of various technologies to be conducted. However, caution needs to be exercised. Looking at various MACCs it is clear to see that industrial motors and compressed air are an effective way to reduce energy use (see box out). The thing about compressed air systems is that they contain a wealth of opportunities such as the motor driving the compressor, whether it needs a variable speed drive (VSD), pipework, site configuration, heat recovery and control systems among others. So, it becomes a question of either looking at the complete system or individual components thereof.

Energy saving opportunities

MACCs offer a clear, evidence-based method for prioritising energy efficiency investments. Compressed air systems consistently rank among the most cost-effective opportunities for reducing energy use and carbon emissions. Alongside industrial motors, they can deliver both financial and environmental benefits when optimised.

According to the Carbon Trust, UK businesses could save up to £110 million annually by making simple low-cost improvements to compressed air systems and processes. A common mistake is to consider the compressor in isolation. Compressing air is inherently energy-intensive, with energy costs accounting for around 80% of a compressor’s total cost of ownership over its lifetime. This makes whole-system thinking essential.

One of the most significant yet often underutilised opportunities lies in heat recovery. As much as 94% of the electrical energy used to power an air compressor is converted into heat. Without a recovery system, this energy is lost to the atmosphere. Heat recovery systems capture this waste heat and repurpose it for space heating, domestic hot water, or other on-site processes. This can reduce reliance on gas or electric heating systems, resulting in substantial savings and lower carbon emissions. The benefits are especially pronounced in facilities with continuous hot water needs, such as those in the food and drink sector, pharmaceuticals, and industrial cleaning. As energy prices rise and pressure to decarbonise increases, heat recovery has become one of the most effective upgrades available for compressed air systems.

Leak detection is another key area for improvement. The average facility loses around 30% of its compressed air through leaks, with some sites seeing significantly higher figures. Identifying and repairing these leaks can have an immediate impact on energy use. Reducing system pressure is equally effective. For every bar that system pressure is lowered, energy consumption typically falls by around 7%. Many systems are set to run at unnecessarily high pressures, which drives up costs without adding operational value.

Ambient temperature also plays a role in system efficiency. Cooler intake air increases compressor performance, with a 5°C reduction in ambient temperature delivering energy savings of up to 1.5%. Ensuring compressors are kept in clean, cool, and well-ventilated environments also reduces the load on ancillary equipment, such as dryers and filters, helping to reduce total energy use.

Variable speed drive (VSD) compressors present another strong case for energy savings. Unlike fixed-speed models, VSD compressors adjust their output to match real-time demand. This prevents overproduction of compressed air and significantly reduces energy waste. In many applications, VSD technology can deliver energy savings of up to 60%.

Finally, intelligent controls and remote monitoring systems, such as Atlas Copco’s SMARTLINK Energy platform, can help identify inefficiencies across the compressor room. These systems provide actionable insights that support long-term optimisation. In many cases, energy efficiency gains of up to 30% have been achieved by combining data-driven monitoring with targeted system improvements.

Bundling compressed air efficiency projects

It is harder to get larger projects off the ground as they can have payback periods that exceed what most businesses are willing to accept. However, by bundling a whole system of technologies into a broader compressed air energy efficiency project it is possible to get a more acceptable payback period.

The low-hanging fruit, such as leaks in pipework, which may have a one- to two-year payback, combined with better compressors or heat recovery, which could have a five-year payback, can result in an overall payback of three years, meaning that the project has an improved chance of getting the go ahead.

To find out more about improving the energy performance of your compressed air system talk to Atlas Copco.

How a MACC Curve works for compressed air systems:

1. Defining the Baseline: A baseline emissions level for the compressed air system is established.

2. Identifying Abatement Measures: Various measures to reduce emissions are identified, such as improving system efficiency, using renewable energy sources, or implementing leak detection and repair programs.

3. Assessing Costs and Benefits: For each abatement measure, the cost of implementation and the potential for emissions reduction are estimated.

4. Plotting the Curve: The measures are plotted on a graph, with the x-axis representing the amount of emissions reduced and the y-axis representing the cost per unit of emissions reduced (e.g., £/ton of CO2e).

5. Analysing the Curve: The MACC curve helps to:

- Identify cost-effective measures: Measures with lower costs are more cost-effective.

- Determine the optimal level of abatement: The curve can indicate the point where the additional cost of further emissions reduction exceeds the benefits.

- Prioritise investments: The curve can help to prioritize which abatement measures to implement first to maximise the impact on emissions reduction.

For example if a compressed air system has a baseline emissions level of 100 tons of CO2e (carbon dioxide equivalent) and several abatement measures are considered:

- Measure A: Installing a new compressor with higher efficiency, reducing emissions by 10 tons of CO2e at a cost of £10,000.

- Measure B: Implementing a leak detection and repair program, reducing emissions by 5 tons of CO2e at a cost of £2,000.

- Measure C: Switching to renewable energy for the compressed air system, reducing emissions by 20 tons of CO2e at a cost of £40,000.

On the MACC curve, Measure B would appear at the lower end, as it’s the most cost-effective (lowest cost per ton of emissions reduced), followed by Measure A, and then Measure C.