The centre, part of the Everyone Active group, is a large-scale facility that provides a wide range of activities to the local community. The centre is open seven days a week and runs fitness classes and incorporates a gym, two swimming pools and dance studios.

On reviewing the site’s energy consumption as part of the company’s wider environmental strategy, Everyone Active identified there was potential to make vast energy savings by upgrading the air handling units (AHUs).

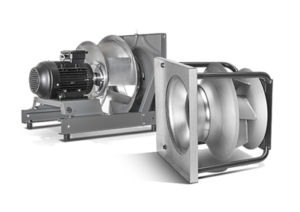

The existing system included several Fläkt Woods’ AHUs that had been operational for over 30 years. Though they had stood the test of time, performance and energy efficiency capabilities of HVAC systems have progressed, so savings could be made.

On surveying the plant room with partners Heasalls Mechanical, the leisure centre group’s M&E contractor, Fläkt Woods found that a plug fan retrofit would offer cost and energy savings for the site. Following a successful trial in the ‘changing village’, all of the existing fans were also upgraded with new Fläkt Woods’ models, in tandem with the existing ABB ACH550 inverter drives.

Stephen Shipman, maintenance manager at Everyone Active, said: “The quality of work and the energy savings have already proven to be outstanding. The fans are also significantly quieter than the models that were previously installed, demonstrating the technological advancement in Fläkt Woods’ products since the original system and plant room were installed.”

“Everyone Active has now employed an energy manager, who is tasked with monitoring the energy consumption at Harrow Leisure Centre. We’ll await the performance data for this initial project, which we are certain will demonstrate vast energy and operation cost savings, and will in turn open the opportunity for us to replicate this solution across our other sites.”

The UK sales service manager at Fläkt Woods, added: “Providing optimal indoor air climate and air quality is integral to any business; however it is of particular importance for leisure facilities, where comfortable air temperatures are imperative.

“For this reason, our AHUs were selected for this project, helping to keep users and staff comfortable. We are certain that these newly installed products will provide a long term, energy efficient solution for another three decades.

“What’s more, through upgrading the previous centrifugal fans to new ErP compliant plug fans, the facility now benefits from reduced energy consumption, electricity load and CO2 emissions – plus as it was a simple and quick process, minimal changes required.”

Fläkt Woods develops, manufactures and distributes ventilation, air climate and fire safety products, as well as full system solutions, for residential, commercial and industrial applications. For more information on the complete range of fans and other ventilation products from Fläkt Woods, visit www.flaktwoods.co.uk.

Click here to see if you qualify for a free subscription to the print magazine, or to renew.

Follow us at @EnergystMedia. For regular bulletins, sign up for the free newsletter.