Altilium, a UK-based clean technology group focused on supporting the transition to net zero, has today announced the results of new research carried out by Imperial College London, which reveal that its recycled EV battery materials can match, and even surpass, the performance of virgin mined materials. The achievement marks a critical milestone in the development of a circular economy for EV battery materials, proving recycled materials are a high-performing and viable alternative to mined metals.

Imperial’s analysis of Altilium’s recycled cathode active materials (CAM) confirmed distinct improvements in purity, morphology and electrochemical performance, compared to commercially available materials. These benefits have the potential to deliver significant improvements in battery performance – including longer battery life, faster charging times and lower costs.

Under the research programme, Imperial carried out extensive electrochemical testing of coin cells and pouch cells manufactured with recycled CAM produced at Altilium’s ACT1 facility in Devon. The results demonstrated superior rate and cycle performance compared to commercially available CAM used in high-nickel NMC 811 batteries. With a cycle cell capacity exceeding 150mAh/g, Altilium’s materials significantly outperformed typical ranges for mined materials.

Analysis of the recycled CAM samples also revealed significant advancements in particle size and distribution, contributing to improved stability and cycling behaviour. Crucially, minor changes observed during testing affirmed the chemical and physical robustness of the recycled CAM, further highlighting its potential for long-term battery performance.

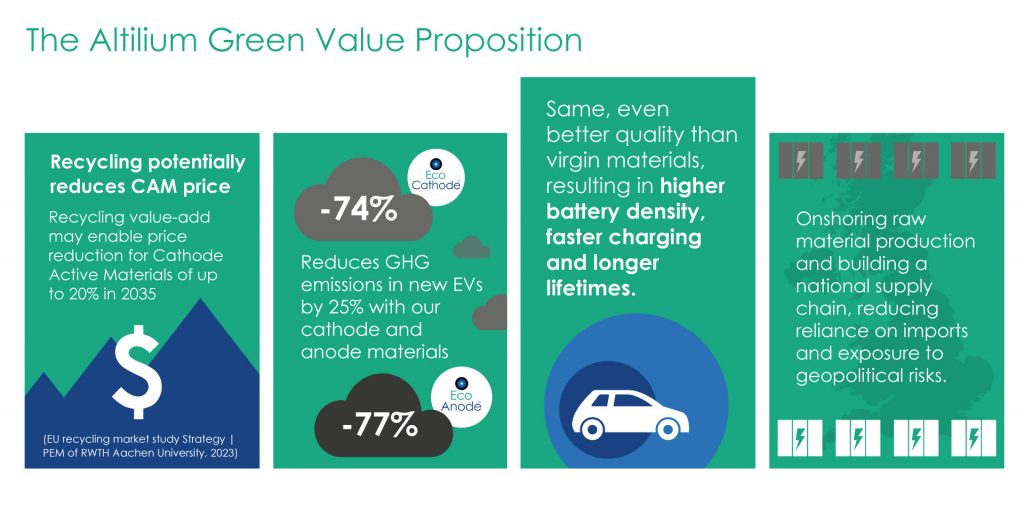

The findings underscore the potential of Altilium’s proprietary EcoCathode process, which is capable of recovering over 95% of critical metals, including lithium, from end- of-life EV batteries. By upcycling these materials into high-quality CAM, Altilium is able to offer UK cell manufactures and automotive OEMS with a sustainable domestic source of high-performance battery materials, helping them to meet their net zero targets and reducing the UK’s reliance on imported virgin materials.

Altilium co-founder COO, Dr Christian Marston, commented, “These results confirm the reliability and superior performance of Altilium’s materials and validate our mission to build a UK champion for EV battery recycling. Recycled CAM not only aligns with global sustainability goals but also offers improved technical performance at a lower cost, making it a game-changer for the EV industry.”

Unlike virgin ores, which vary in quality and require extensive refinement to remove impurities, recycled materials are derived from standardised, manufactured batteries, reducing impurities and variability in metal composition.

Recycled CAM precursors can also retain favourable crystal structures and grain morphology, which can be leveraged during re-synthesis for high-performance materials, while consistent particle sizes aid in the production of CAM with better electrochemical properties.

Furthermore, recycling allows for precise adjustments in CAM composition, enabling the development of nickel-rich or cobalt-free formulations tailored for next- generation EV batteries.

Longer battery life

Higher purity of feed means fewer structural defects and chemical instability in the CAM, leading to improved durability of the battery over time. This translates to longer cycle life and greater reliability under repeated charging and discharging cycles.

The superior morphology of recycled CAM precursors also helps maintain the integrity of the material during cycling, reducing degradation and capacity loss over the battery’s lifespan.

Charging capacity

Consistent particle sizes enhances lithium-ion mobility, improving the rate capability of batteries. This can result in faster charging times without compromising capacity.

In addition, tailored CAM compositions (e.g., nickel-rich formulations) can enhance energy density, supporting batteries with higher capacity and greater range per charge.

Lower cost

Recycling reduces the costly and energy-intensive steps associated with mining, transporting, and refining virgin ores, as well as costs associated with variable ore quality and supply disruptions. Lower energy use during recycling compared to virgin material processing further drives down the carbon footprint and operational expenses.