British battery technologists have co-developed a manufacturing process easing automation in making next-generation cells based on sodium-metal-chloride chemistry.

LiNA Energy, a privately held, six-year old spinoff from Lancaster University, has partnered with Turin-based Comau, a subisidiary of carmaking giant Stellantis, in evolving techniques to accelerate production of the cells, cheaper in their ingredients than lithium-based alternatives.

Focusing on the interface of ceramics and power storage, the British partners have emerged as pioneers in solid-state sodium batteries. But the enterprise realized they needed help in automating their production methods to secure lower cost output.

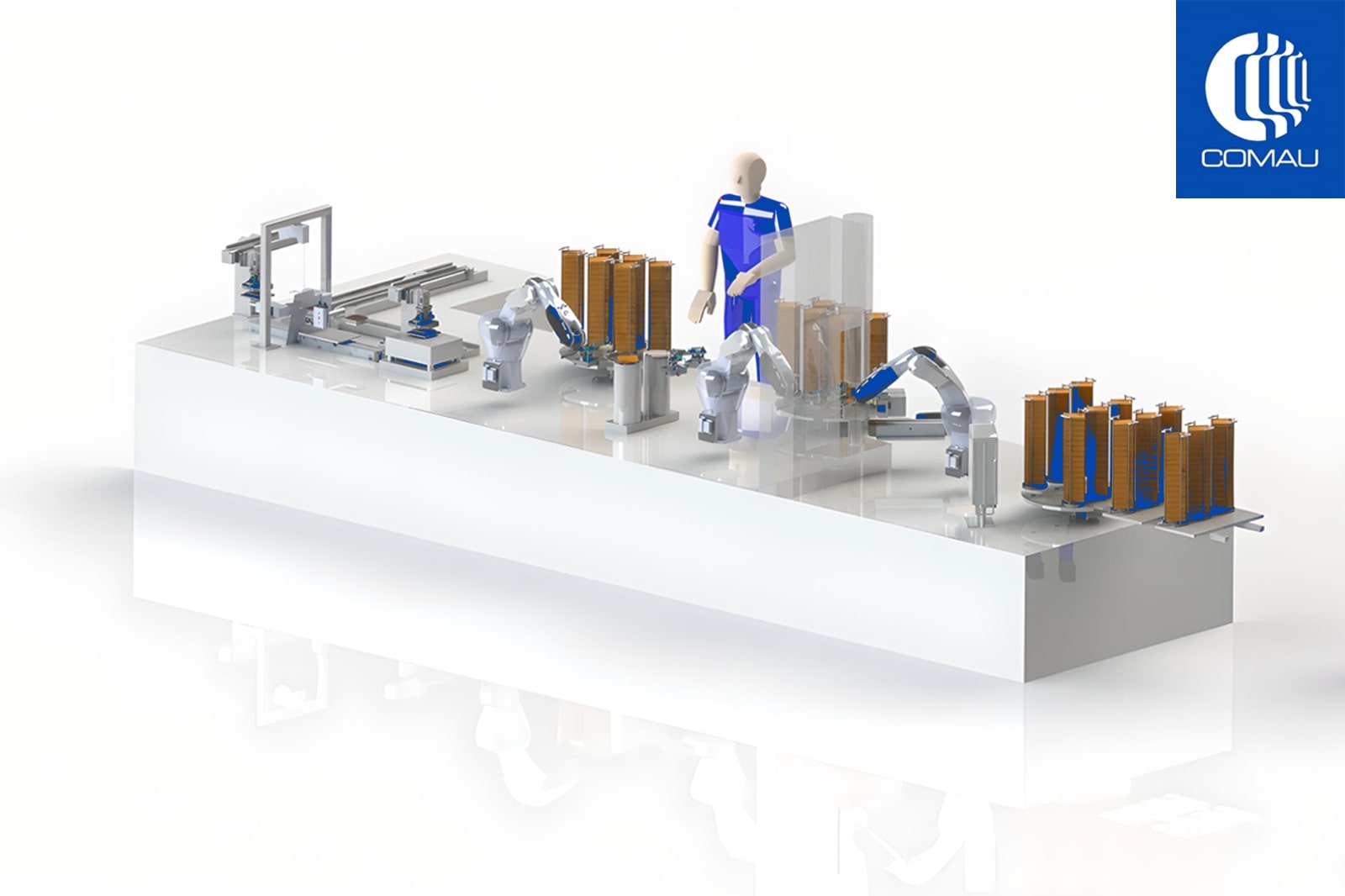

Engineers from both companies collaborated to design enclosure equipment for handling specific components of the solid-state battery cells. Via trials in Comau’s cleanroom, they also came up with robot-enhanced solutions in identifying and integrating existing commercially available equipment.

Joint working enabled Comau to suggest improvements to LiNa’s manufacturing, resulting in optimised process dynamics as the Brits move to automated assembly of cells.

Advances in sodium-based battery cells are driving the deployment of a safe, sustainable energy source that can be used at high temperatures. Instead of completely replacing lithium-ion batteries, next-generation solid-state sodium batteries will provide high performance energy storage which is both cost efficient and can be optimised to integrate power from renewable sources, not least in high growth solar markets such as India.

“This automated manufacturing concept, designed with Comau’s engineering team, provides a clear technology roadmap to increase significantly production capacity of our patented battery cells,” said Kris Barr, LiNA’s operations director.

“After successfully researching process dynamics and finalised an innovative design proposal“, Barr went on, “we are looking forward to taking the next steps in our mission to commercialise our sustainable, low-cost solid-state sodium batteries.”

LiNA Energy says its sodium-metal-chloride solution is built around proven technology established on 1980s sodium chemistry, and refined with advances in modern materials science. Sodium-based raw materials are abundant, adding to its batteries’ attractiveness to high volume manufacturers.

Offering greater safety, performance and sustainability in its devices, the UK company says it can commercialise them faster through shortened development lag time.

Comau’s expertise spans the value chain of battery production, from prototyping and pre-production to mass production and the recycling of end-of-life units. The company collaborates with the world’s leading electric vehicle manufacturers and actively participates in numerous projects promoted by the European Union for the development of e-Mobility technologies.