The route to making green hydrogen looked to have eased significantly today, as two technology giants allied to cut up to 90% of valuable iridium from production methods behind the industry’s favourite electrolyser producing the gas.

Toshiba and specialist technologists Bekaert unveiled a co-operation deal on a new method to fabricate PEMs, proton exchange membranes, an essential component of the next generation, water-splitting devices.

PEMs are the core of the scalable hydrogen electrolysers which Sheffield-based ITM Power builds on Europe’s biggest specialist factory on the city’s Bessemer Park. ITM intends to make 5GW of its devices this year.

Toshiba Energy Systems and Belgian wire fabricators Bekaert signed a global pact, sharing manufacturing licenses for Membrane Electrode Assemblies (MEA), a key component for Proton Exchange Membrane (PEM) electrolysers. The deal builds on an exploratory agreement signed in September 2023.

PEM electrolysers use electricity to split water into its component elements of oxygen and hydrogen. When the electricity is from a renewable energy source, the hydrogen is produced without any greenhouse gas emissions. The catalyst in PEM anode electrodes uses iridium, one of the scarcest traded metals.

Solutions that reduce iridium content thus present a significant break-through towards the scale adoption of the technologies.

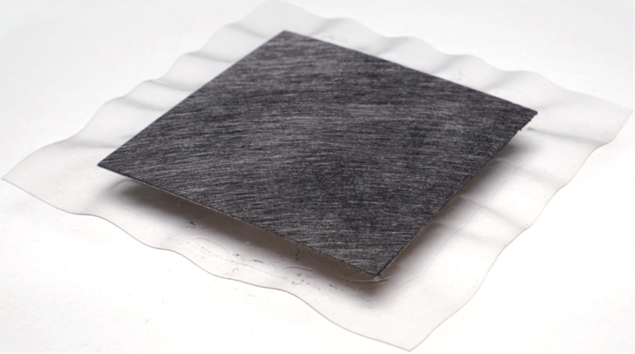

Under the agreement, Bekaert’s leading expertise in Porous Transport Layers (PTL), a key component in the MEA of water electrolysers, will be coupled with Toshiba’s innovative iridium-saving technology for MEA, which will enable a 90% reduction in iridium usage in the production of PEM electrolysers.

This reduction in iridium will enable a more stable supply of MEA and support the scale expansion of green hydrogen production.

Bekaert will undertake commercialisation of MEA production, leveraging its global network addressed from Belgium, to serve its hydrogen customers. Toshiba will license its iridium-saving MEA technology to Bekaert, granting them the ability to manufacture and distribute MEAs.

Toshiba will also focus on further enhancing its technical performance of the technology. The agreement is global, with the exception of Japan-related projects, which will be subject to a separate agreement.

Inge Schildermans, senior vice-president of Bekaert’s Energy Transition business commented: “Bekaert is a leading player in the development of green hydrogen production and is therefore delighted to partner with Toshiba on the industrialization and commercialization of this innovative new PEM MEA technology.

“Furthermore, we are delighted to be able to offer this to our green hydrogen customers and help them achieve their cost and sustainability challenges. Bekaert is establishing itself as a green hydrogen technology and industrialization partner, helping the electrolyzer industry to scale and deliver the energy transition.”

Shigehiro Kawahara, Vice-President of Toshiba ESS commented: “Addressing the surging demand for green hydrogen requires wider adoption of PEM electrolysis equipment. Our advanced iridium-saving MEA technology, coupled with Bekaert’s longstanding expertise in PTL, forms a promising partnership. We believe this collaboration will effectively meet the rapid growth in demand and contribute significantly to the realization of a green hydrogen society.”