Sodium-ion batteries are being developed due to potential costs, safety, sustainability and performance characteristics over traditional lithium-ion batteries suggests IDTechEx’s new report, “Sodium-ion Batteries 2024-2034: Technology, Players, Markets, and Forecasts”. Sodium is significantly more abundant than lithium and can use aluminium for the anode current collector instead of copper, reducing supply chain risks, comments author and Senior Technology Analyst at IDTechExSodium, Shazan Siddiq. Furthermore, it can be stored at zero volts, causing less risk during transportation as lithium-ion batteries are generally stored at around 30% charge, while the electrolytes used in sodium-ion systems generally have a higher flashpoint than lithium-ion, reducing flammability risks. Another advantage is the process for making sodium-ion batteries is similar to lithium-ion, allowing scale-up of the technology from existing lithium-ion battery production lines.

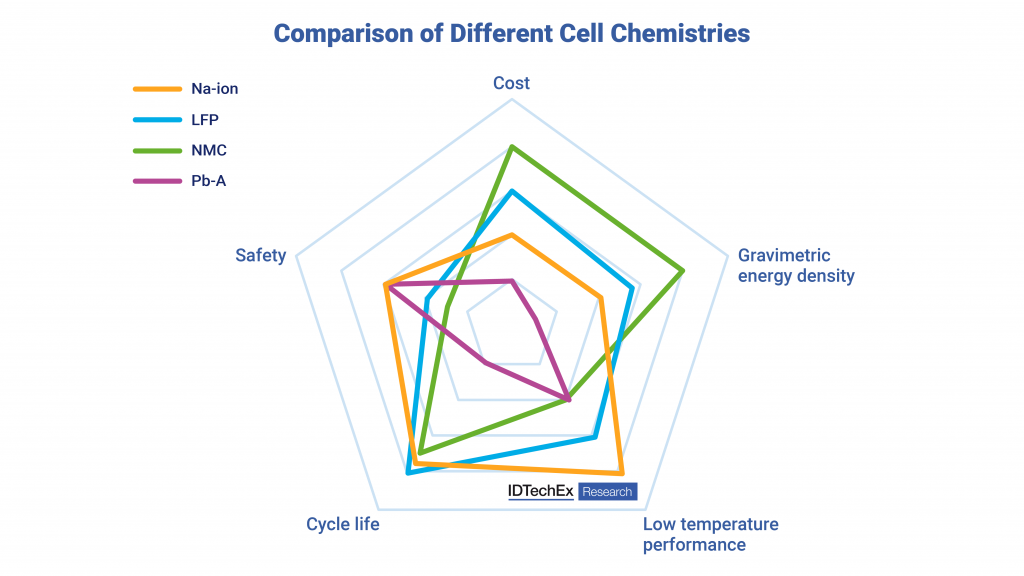

Comparing the different performance characteristics, one can see the general pros and cons of each battery chemistry, see above. The energy density for sodium-ion batteries is still lower than high-energy lithium-ion cells, which use nickel, but it is approaching the energy density of high-power lithium iron phosphate (LFP) cells. The cycle life of cells is reasonable in some configurations, but one of the interesting elements not shown in the image is that sodium-ion batteries can have quite high-power characteristics with reports of ~1000W/kg, which is higher than NMC (~340-420W/kg) and LFP (~175-425W/kg) cells. They also exhibit better low-temperature performance.

Sodium is a heavier element than lithium, with an atomic weight 3.3 times greater than lithium (sodium 23g/mol vs lithium 6.9g/mol). However, it is important to note that lithium or sodium in a battery only accounts for a small amount of cell mass and that the energy density is mostly defined by the electrode materials and other components in the cell. Hence, while current sodium-ion batteries have relatively low energy densities, there is the potential for this to increase in the coming years.

Cost comparison

It has been estimated that at scale, a sodium ion battery with a layered metal oxide cathode and hard carbon anode will have ~25 to 30% lower material costs than an LFP battery. Unpacking this a bit more, it is known that two of the main differences between a sodium-ion cell versus a lithium-ion cell is that they replace lithium and copper with cheaper sodium and aluminium, which gives around a ~12% cost reduction.

The IDTechEx report compares the costs of different lithium-ion and sodium-ion battery configurations to find that there are potential cost advantages, but the exact number depends heavily on the chemistry being used. In the near term, this is likely to be a battery with a sodium-layered metal oxide cathode with a hard carbon anode, but in the future, the cathode may well improve with some viewing future anodes having a blend of phosphorus, which has a higher specific capacity. It is important to note that material prices do vary, and there is still uncertainty around future material performance.

The sodium-ion chemistry will certainly not be the answer for all applications; however, it can complement, rather than displace, existing and future lithium-ion technologies in many applications. The new report from IDTechEx, “Sodium-ion Batteries 2024-2034: Technology, Players, Markets, and Forecasts”, covers over 25 industry players and includes granular 10-year forecasts, patent analysis, material and cost analysis, and identifies target markets for this emerging beyond-lithium technology.

To find out more, including downloadable sample pages, please click here.